Product Description

product.

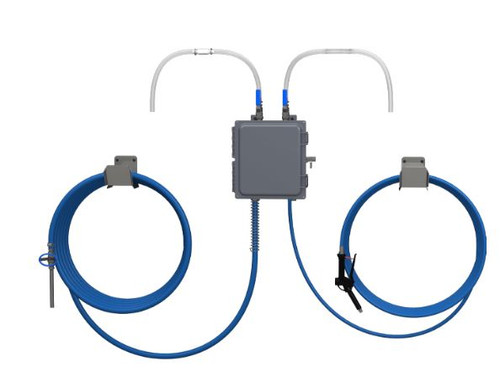

product.- One central pump distributes pre-mixed solution through header system

- Pump and doorway nozzles sold separately

- Up to 25 ft. (7.6 m) total distance between control box and nozzle

- Powered by air and electricity

- Repeat cycle timer

SPECIFICATIONS:

- power type - Central System, Electricity

- chemical pickup type -Supplied with pre-mixed solution from a central system

- number of products unit can draw from - Supplied with one product

- flow rate* - 2 gal/min (7.6 l/min)

- timer operation type - Repeat cycle

- coverage area - With one nozzle: 9×4 ft. (2.7×1.5m) - With two nozzles: 5×3 ft. (2.4×1.2m) at each nozzle

- product height - 15 inches (38.1 cm)

- nozzle type - Single-line poly nozzle assembly (GK6T) (Sold separately)

- number of nozzles - One control box can support up to 2 nozzle assemblies

- distance from nozzles to control box - The combined distance between the control box and the nozzle(s) must equal 25 ft. (7.6 m) or less

- tubing/fitting sizes - Designed for use with 1/2 in. (12.7 mm) outside diameter tubing between control box and nozzle(s)

REQUIREMENTS:

- compressed air requirements - 40-80 psi (3.5 bar) with 5-10 cfm (141-283 l/min)

- liquid temperature range - 40-100°F (4.4-37°C)

- electrical requirements - 120 VAC at 60 Hz, 2 amps (GFCI protected outlet)

- operating voltage - 120 VAC

- central system requirements - Pre-mixed solution must be supplied by a properly sized header system at 2 gpm and 40-80 psi (3-5 bar)

- chemical compatibility - Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or SDS for your product or contact our customer service department.

*Dilution rates and flow rates given are based on chemical with viscosity of water and factory air pressure settings.