Product Description

product.

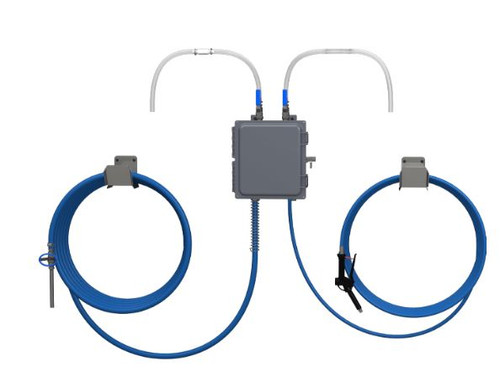

product.- Drop station for central foam system - Pump and nozzles sold separately

- Two foam systems built inside a shared enclosure – systems must run independently

- Distributes pre-mixed solution through header system

- Powered by compressed air

- Stainless steel ball valve and wand

- Stainless steel fluid fittings

- Color coding options Discharge hose – 4 colors (BL, GN, YL, RD)

- Ability to add padlock to box

| COMPRESSED AIR REQUIREMENTS | 40-80 psi (3-5 bar) with 3-5 cfm (84.9-141 l/min) |

|---|---|

| LIQUID TEMPERATURE RANGE | 40-100˚F (4.4-37˚C) |

| CHEMICAL COMPATIBILITY | Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or MSDS for your product or contact our customer service department. |

| POWER TYPE | Central System |

|---|---|

| CHEMICAL PICKUP TYPE | Supplied with pre-mixed solution from a central system |

| NUMBER OF PRODUCTS UNIT CAN DRAW FROM (AND WHETHER IT DRAWS SIMULTANEOUSLY OR ONE AT A TIME) | Supplied with TWO products |

| SUCTION LINE LENGTH/DIAMETER | -- |

| DISCHARGE HOSE DIAMETER/LENGTH | 50 ft. (15 m) hose with 3/4 in. (19 mm) inside diameter. |

| DISCHARGE WAND/TIP TYPE | 7 in. (17.8 cm) stainless steel wand with zero tip and ball valve |

| OUTPUT DISTANCE | 25-30 ft. (7-9 m) |

| OUTPUT VOLUME | 20-45 gal/min (75-170 l/min) |

| FLOW RATE* | 2 gal/min (7.6 l/min) |

| tubing/fitting sizes | 4 ft. (1.2 m) chemical inlet hose with 1/2 in. (12.7 mm) inside diameter and 1lb check valve |

*Dilution rates and flow rates given are based on chemical with viscosity of water and factory air pressure settings.